Understanding aluminum casting and its uses across industries

Checking Out the Ingenious Procedures Behind Modern Light Weight Aluminum Shop Procedures

Modern aluminum factory procedures are undertaking substantial makeover. Automation and AI are improving production approaches, enhancing both effectiveness and precision. The combination of 3D printing is enhancing mold and mildew creation, while sustainability techniques are ending up being more essential. Each of these improvements plays a vital role in redefining the sector. Nevertheless, the effects of these adjustments extend beyond mere production effectiveness. What obstacles and chances exist ahead for aluminum shops in this progressing landscape?

The Function of Automation in Light Weight Aluminum Foundries

Additionally, automation contributes to improved safety and security criteria within the factory setting. By transferring dangerous jobs to makers, human employees can concentrate on managerial duties and quality assurance, reducing the threat of mishaps. On top of that, data analytics stemmed from automated procedures offer beneficial understandings into functional efficiency, bring about much better decision-making and constant renovation. As the need for light weight aluminum products expands, the adoption of automation innovations will likely broaden, even more changing the landscape of light weight aluminum shop operations.

Improvements in Casting Technologies

Current advancements in casting technologies are changing light weight aluminum foundry procedures. Advancements such as 3D printing assimilation, advanced alloy solutions, and automated procedure optimization are enhancing efficiency and item high quality. These growths are critical in meeting the developing needs of the market.

3D Printing Assimilation

Integrating 3D printing innovation right into aluminum foundry operations has actually reinvented traditional casting methods, improving both effectiveness and precision. This innovative technique permits the rapid manufacturing of complex molds and cores, substantially decreasing preparations and product waste. By making use of additive manufacturing, factories can develop detailed geometries that were difficult or formerly tough to achieve with conventional methods. The adaptability of 3D printing also allows fast layout modifications, fostering an extra active production procedure. Furthermore, this assimilation sustains using light-weight structures, which is increasingly crucial in industries such as automobile and aerospace. As aluminum foundries remain to take on 3D printing, they place themselves at the leading edge of technological advancement, driving improvements in product top quality and functional abilities.

Advanced Alloy Formulations

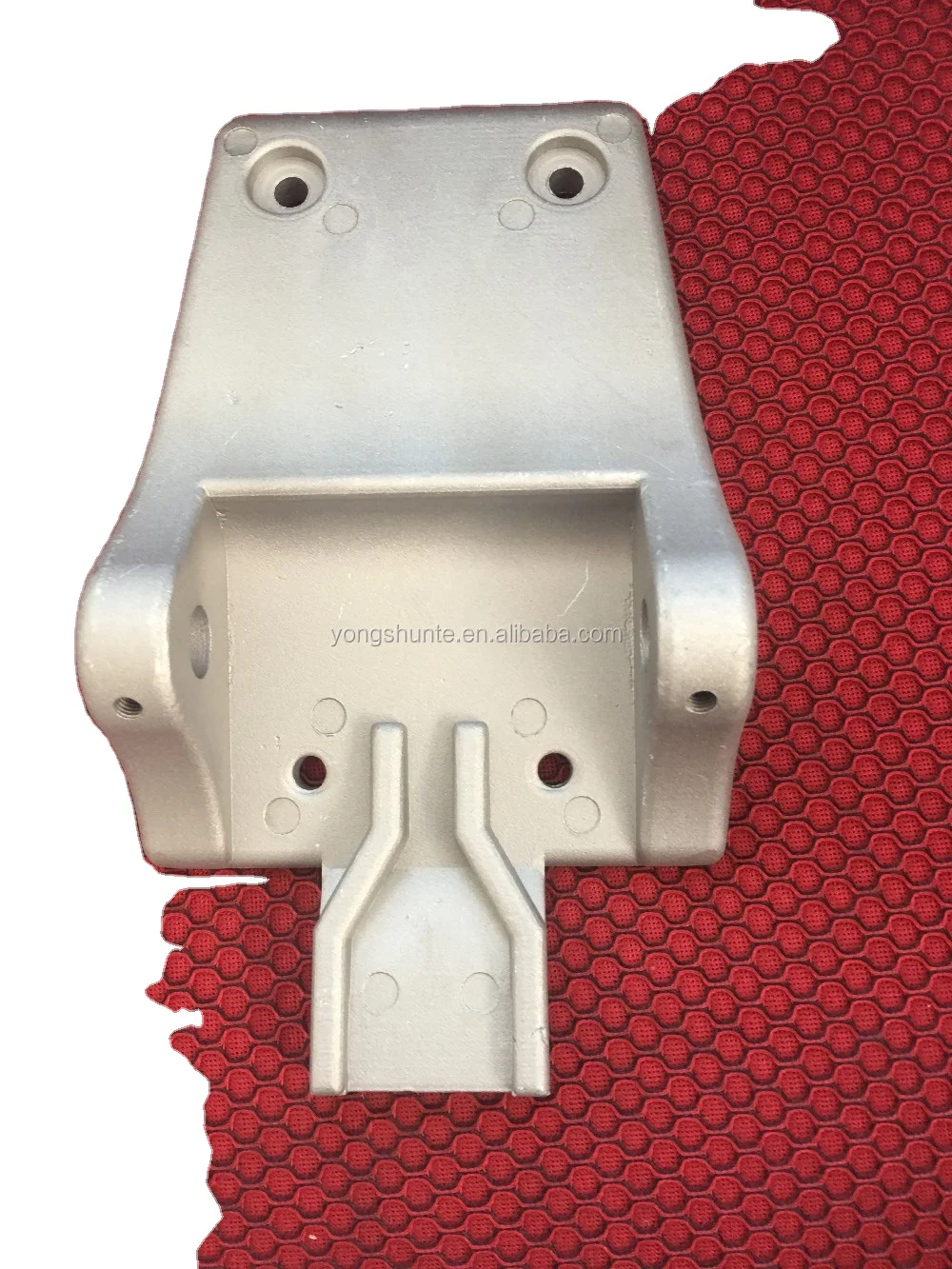

The advancement of advanced alloy formulas has significantly enhanced casting technologies in light weight aluminum foundry procedures. These solutions integrate numerous aspects, such as silicon, copper, and magnesium, to enhance mechanical residential or commercial properties and thermal resistance. By tailoring the composition of aluminum alloys, suppliers can accomplish specific performance qualities that fulfill the demands of varied applications, from automobile components to aerospace frameworks. Using innovative alloys likewise contributes to minimized weight and enhanced toughness, which are essential consider modern design. In addition, advancements in alloy development make it possible for far better fluidity throughout casting, leading to improved surface area coatings and reduced flaws. In general, progressed alloy formulations stand for a substantial leap onward, positioning aluminum foundries to satisfy the evolving requirements of various industries successfully.

Automated Process Optimization

Advancements in casting modern technologies have led the way for automated process improvement in aluminum foundry procedures. By incorporating advanced software and real-time information analytics, shops can currently improve production procedures and improve quality assurance. Automated systems monitor variables such as temperature, cooling, and pressure prices, enabling immediate changes that decrease issues and waste. In addition, machine discovering formulas analyze historic performance information to predict excellent setups, thereby boosting effectiveness and reducing cycle times. Robotics additionally play a significant role, handling repetitive tasks that boost safety and accuracy. Generally, these technologies not only drive functional effectiveness however likewise allow factories to satisfy the growing need for top notch light weight aluminum elements in various industries.

Smart Production and Market 4.0 Integration

The assimilation of Smart Production and Market 4.0 within aluminum shops is transforming operational effectiveness. By leveraging IoT innovations, automation, and robotics, foundries can enhance manufacturing procedures and minimize downtime. Additionally, information analytics supplies essential insights that improve decision-making and drive continuous renovation.

IoT in Shop Operations

As suppliers significantly accept the Net of Points (IoT), shop operations are experiencing a transformative change in the direction of wise production and Sector 4.0 assimilation. aluminum casting. IoT modern technologies enable real-time information collection and evaluation, enhancing decision-making procedures and operational effectiveness. Sensing units and linked gadgets keep an eye on tools performance, product use, and environmental conditions, enabling proactive maintenance and resource optimization. This connection promotes a much more agile production setting, where changes can be made quickly in response to market demands. Furthermore, IoT promotes improved traceability and quality assurance, as data from the whole production cycle can be easily accessed and examined. Generally, the assimilation of IoT in foundry operations significantly boosts performance and drives innovation in aluminum manufacturing procedures

Automation and Robotics Integration

Automation and robotics combination is transforming light weight aluminum foundry procedures by boosting performance and accuracy. This transformative technique simplifies processes such as molding, putting, and completing, reducing human mistake and enhancing outcome consistency. By using advanced robotic systems, foundries can accomplish higher production rates while preserving rigorous top quality criteria. Automated systems also enable real-time monitoring and flexible control, enabling speedy adjustments to manufacturing criteria. Furthermore, the integration of robotics decreases labor prices and minimizes security threats related to hands-on handling of liquified metal. As shops welcome wise production concepts integral in Sector 4.0, the synergy in between automation and robotics solidifies their competitive side, paving the method for sustainable development and development in the aluminum casting field.

Data Analytics for Performance

Using information analytics substantially boosts efficiency within light weight aluminum factory procedures, straightening with smart manufacturing and Market 4.0 concepts. By leveraging real-time data collection original site and evaluation, factories can keep track of manufacturing processes, forecast equipment failures, and maximize source appropriation. This data-driven technique facilitates insightful decision-making, making it possible for managers to enhance and determine traffic jams operations. In addition, predictive analytics equips foundries to anticipate market needs, thus minimizing waste and making sure timely product shipment. Assimilation of data analytics with IoT tools enhances functional presence, cultivating an aggressive maintenance culture. Inevitably, implementing these advanced logical strategies not only enhances efficiency however additionally drives advancement, positioning aluminum foundries to satisfy the evolving demands of the market while preserving one-upmanships in a swiftly changing landscape.

Sustainable Practices in Aluminum Spreading

While the aluminum casting industry has actually traditionally dealt with environmental obstacles, several factories are now embracing sustainable techniques to alleviate their effect (aluminum casting). A significant focus has actually been on recycling aluminum scrap, which not just reduces waste however additionally conserves power contrasted to primary light weight aluminum production. Cutting-edge melting modern technologies, such as induction furnaces, enhance energy performance and lower greenhouse gas discharges

Additionally, foundries are executing closed-loop water systems to decrease water intake and minimize thermal pollution. Using environment-friendly binders in mold-making procedures is getting traction, further decreasing hazardous exhausts.

Some centers are investing in renewable power resources to power operations, straightening with global sustainability goals. By integrating these techniques, the aluminum casting industry is evolving towards a much more ecologically accountable future, showing that economic development can exist together with environmental stewardship - Aluminum Casting Company. These efforts reflect a dedication to sustainability and the value of environmental liability in production

Quality Assurance Innovations

As the light weight aluminum casting sector developments towards sustainability, the significance of quality control innovations comes to be increasingly evident. Modern aluminum factories are embracing sophisticated modern technologies to enhance their high quality assurance procedures. Techniques such as real-time monitoring and data analytics enable makers to identify issues and disparities early in the production cycle. Implementing automatic examination systems furnished with maker discovering algorithms assurances that products satisfy rigid top quality standards while reducing human error.

Furthermore, the assimilation of non-destructive screening approaches, such as radiographic and ultrasonic assessments, gives deeper insights into the integrity of spreadings without harming the material. These innovations not just enhance item integrity but additionally reduce waste, lining up with sustainability goals. On top of that, the adoption of standardized high quality structures assists streamline operations throughout various factories, ensuring uniformity in outcome. Jointly, these innovations are reshaping high quality control, fostering a culture of quality within the light weight aluminum spreading industry.

Future Patterns in Light Weight Aluminum Factory Workflow

What developments lie in advance for light weight image source aluminum factory operations? The future of aluminum factories is poised for change through innovations in automation, fabricated intelligence, and sustainable techniques. The combination of robotics and automated systems is expected to boost effectiveness and precision in the spreading processes, reducing human mistake and labor prices. Additionally, AI-driven analytics will certainly allow real-time monitoring and anticipating upkeep, maximizing functional efficiency and decreasing downtime.

Sustainability continues to be a centerpiece, with foundries increasingly embracing environmentally friendly methods, such as making use of recycled aluminum and establishing low-emission melting technologies. Technologies in 3D printing are also prepared for to reinvent mold-making, enabling complex geometries and minimized product waste. As the market embraces digitalization, data-driven decision-making will end up being pivotal, making it possible for foundries to respond quickly to market needs. Collectively, these trends promise to redefine aluminum shop operations, making them a lot more efficient, sustainable, and versatile to future challenges.

Often Asked Concerns

What Precaution Are Implemented in Light Weight Aluminum Shop Operations?

Aluminum foundry procedures execute various precaution, including individual protective devices, ventilation systems to manage fumes, normal safety and security training, emergency situation action plans, and strict monitoring of temperature and tools to stop accidents and guarantee worker safety and security.

Just How Do Shops Manage Labor Force Training for New Technologies?

What Materials Are Commonly Reused in Light Weight Aluminum Foundries?

Light weight aluminum foundries frequently reuse scrap light weight aluminum, consisting of post-consumer products like drink canisters, automobile components, and building products. This reusing process lowers waste and preserves resources, adding to a more lasting light weight aluminum manufacturing sector.

How Does Aluminum Spreading Impact the Atmosphere?

Light weight aluminum casting effects the setting through energy-intensive procedures, greenhouse gas exhausts, and prospective local contamination. Improvements in reusing and lasting methods can minimize these results, advertising a much more environmentally friendly method to aluminum manufacturing.

What Are the Normal Lead Times for Light Weight Aluminum Spreading Projects?

Typical lead times for light weight aluminum casting read here projects differ considerably, generally ranging from 2 to six weeks. Factors influencing these timelines consist of complexity, order size, and material availability, impacting general production timetables in foundry procedures.

Automation progressively plays a necessary role in light weight aluminum shops, improving effectiveness and precision in the production process. Developments in casting innovations have paved the means for automated process improvement in light weight aluminum shop procedures. Utilizing data analytics greatly improves performance within aluminum factory procedures, aligning with wise manufacturing and Sector 4.0 concepts. A considerable focus has been on recycling aluminum scrap, which not just decreases waste however also conserves energy contrasted to primary aluminum production. Aluminum shops typically reuse scrap light weight aluminum, including post-consumer products like beverage cans, vehicle components, and construction products.